Grain refiners are essential agents used in metallurgy and materials science to control the grain size and structure of metals during solidification. In metallic materials, “grains” refer to the crystallized particles that form as the metal solidifies from a molten state. These grains influence the mechanical properties, strength, and workability of metals. Controlling the size of these grains is crucial, as finer grains can enhance material properties such as tensile strength, hardness, ductility, and resistance to cracking.

This article explores what is a grain refiner, their composition, how they work, their effects on metal properties, and their applications across various industries. By understanding grain refiners and their mechanisms, we gain insights into how engineers and scientists manipulate material properties for applications ranging from construction and automotive manufacturing to aerospace and electronics.

1. Introduction to Grain Refiners and Metal Grain Structure

In metallic materials, grains are the small, individual crystals that form as a liquid metal cools and solidifies. The boundaries between these grains, called grain boundaries, play a significant role in determining the metal’s properties. Metals with finer grain structures generally exhibit improved strength and ductility compared to those with larger grains.

A grain refiner is an additive introduced to the molten metal before it solidifies, which acts to promote the formation of smaller, more uniform grains. These refiners are widely used in metallurgical processes, particularly in the production of aluminum, steel, titanium, and copper alloys, where improved mechanical properties are often desirable.

The role of grain refiners in metallurgy has gained importance as industries demand materials that offer superior performance, durability, and workability. Grain refiners enable the production of metals with controlled microstructures, which can lead to enhanced mechanical properties and improved resistance to various stresses.

2. The Concept of Grain Size and Its Impact on Material Properties

2.1 What Is Grain Size?

Before answering “what is a grain refiner” lets look at grain size. Grain size refers to the average size of the individual crystals, or grains, within a solidified metal. Metals with smaller, finer grains are said to have a “fine-grained” structure, while those with larger grains are described as “coarse-grained.” The grain size in metals is a critical factor in determining several properties, including strength, hardness, ductility, and toughness.

Grain size can vary widely depending on factors such as the cooling rate of the metal, the composition of the alloy, and the presence of grain refiners.

2.2 The Role of Grain Boundaries in “what is a grain refiner”

Grain boundaries are the interfaces where different grains meet within the metal. These boundaries act as obstacles to the movement of dislocations, which are imperfections in the crystal structure that move under stress and contribute to deformation. By hindering dislocation movement, grain boundaries enhance the metal’s strength.

When a metal has finer grains, it has more grain boundaries, which in turn can improve its resistance to deformation. This relationship between grain size and strength is known as the Hall-Petch relationship: as grain size decreases, the metal’s strength and hardness increase.

3. What is a Grain Refiner?

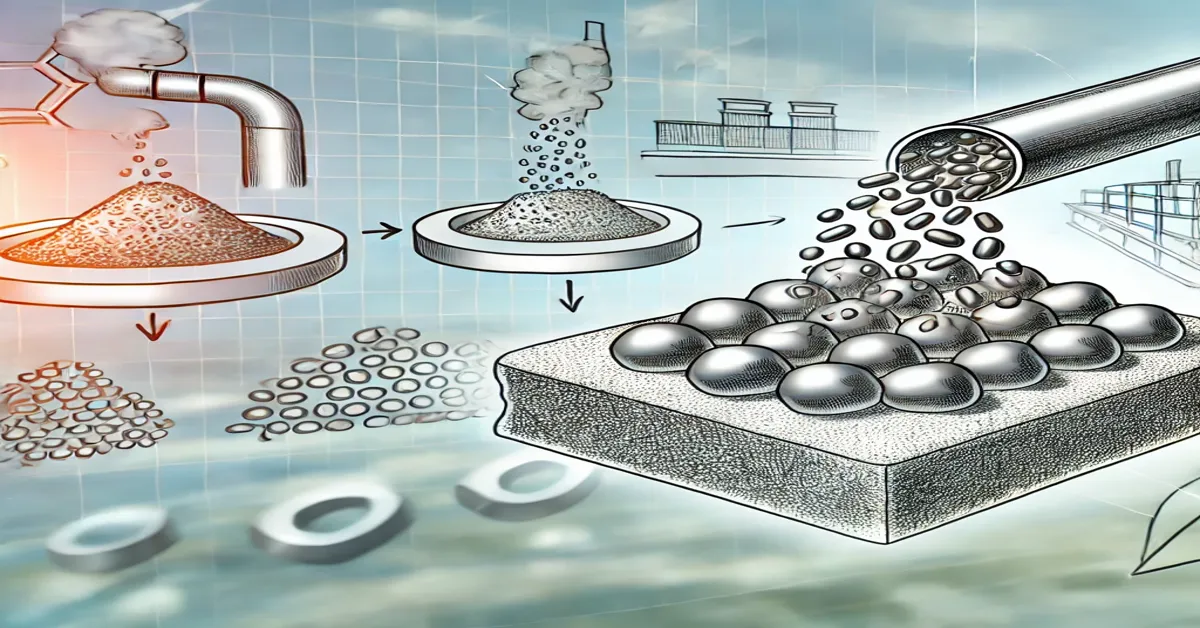

Grain refiners are typically chemical additives, compounds, or elements added to molten metal to promote the formation of fine-grained structures. These additives act as nucleation sites, encouraging the formation of smaller grains during the solidification process. Common grain refiners include materials like titanium, boron, and zirconium, which are added in specific ratios depending on the desired metal properties.

Grain refiners are particularly valuable in the production of aluminum alloys, where they have been shown to significantly improve strength and ductility. Other metals and alloys, such as steel, copper, and magnesium, also benefit from grain refining techniques, leading to improved mechanical properties and durability.

3.1 Types of Grain Refiners

When answering “what is a grain refiner ” let us talk about their Grain refiners can vary depending on the base metal and desired properties. The most commonly used grain refiners include:

- Titanium-Boron (Ti-B) Alloys: Used extensively in aluminum alloys to reduce grain size and improve mechanical properties.

- Titanium-Carbon (Ti-C) and Titanium-Aluminum-Boron (Ti-Al-B): These are also used in aluminum alloys to promote fine-grained structures.

- Zirconium: Often added to magnesium alloys to improve grain refinement and enhance corrosion resistance.

- Niobium, Vanadium, and Manganese: These elements are used as grain refiners in steel to improve strength and resistance to wear.

- Aluminum-Titanium-Boron (Al-Ti-B): Commonly added to aluminum alloys to create a refined, fine-grained structure, improving both strength and corrosion resistance.

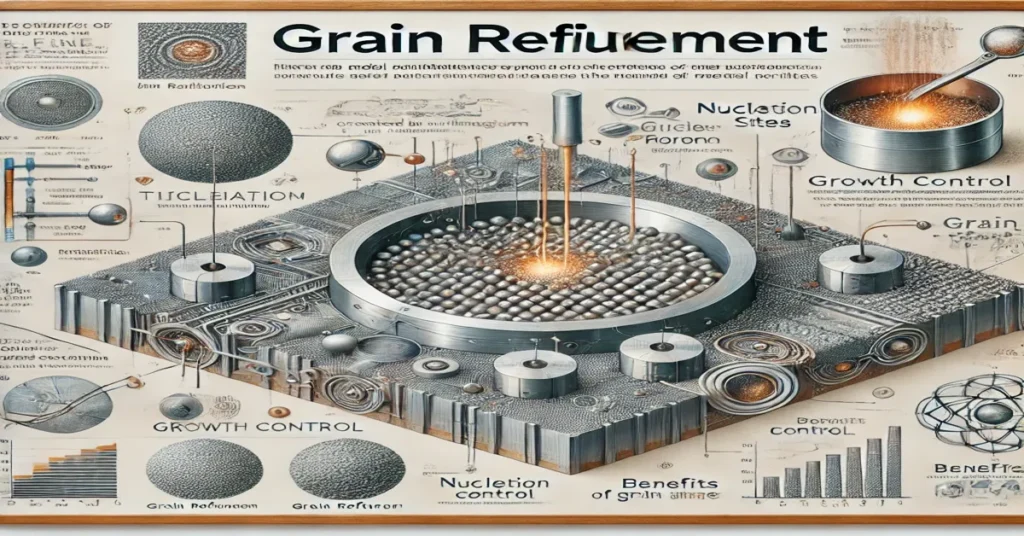

3.2 How Grain Refiners Work

Along with answering the question of “what is a grain refiner” let us look how they work. Grain refiners function by creating nucleation sites within the molten metal. During solidification, these nucleation sites facilitate the formation of multiple small grains instead of fewer large grains. The process of grain refinement begins as the metal cools, with the grain refiner particles acting as catalysts for the formation of crystal structures. By increasing the number of nucleation sites, grain refiners limit the growth of each individual grain, resulting in a fine-grained microstructure once the metal solidifies.

4. Mechanisms of Grain Refinement

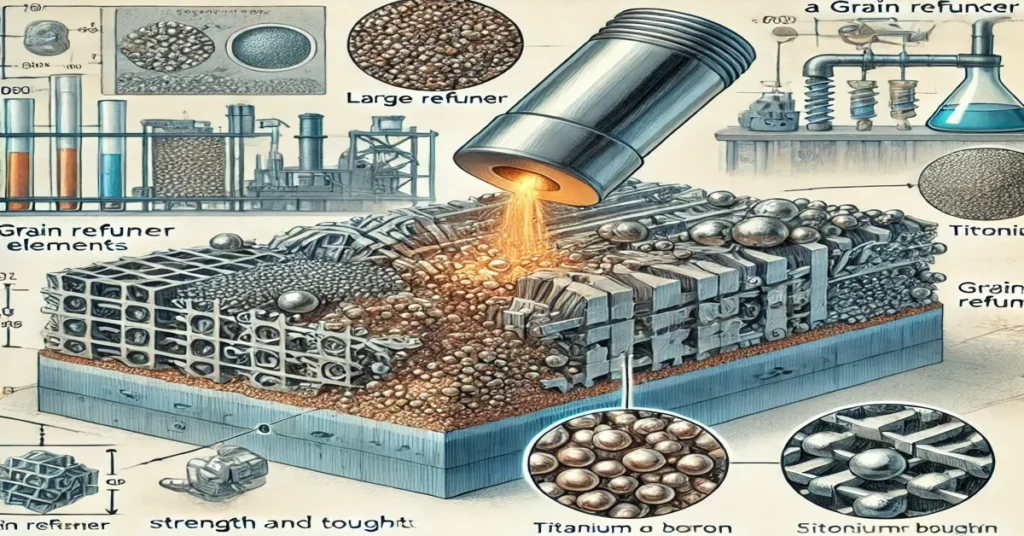

The effectiveness of grain refinement depends on several factors, including the composition of the grain refiner, its concentration in the molten metal, and the cooling rate of the metal. There are two main mechanisms by which grain refiners operate:

4.1 Heterogeneous Nucleation

Heterogeneous nucleation is the primary mechanism through which grain refiners work. In this process, grain refiner particles act as sites, or “nuclei,” around which metal grains begin to form. These particles are typically insoluble in the molten metal, allowing them to remain intact as the metal cools. As nucleation occurs on these particles, smaller grains are formed, leading to a fine-grained structure throughout the metal.

4.2 Growth Restriction

In addition to promoting nucleation, certain grain refiners restrict grain growth by limiting the amount of material available for each grain to consume as it forms. This restriction results from the presence of specific alloying elements, such as boron or titanium, which reduce the diffusion rates within the molten metal, thereby limiting grain growth.

This dual mechanism—nucleation and growth restriction—is why grain refiners are so effective in creating a uniformly fine-grained structure, which is beneficial for improving metal properties.

5. Benefits of Grain Refinement on Metal Properties

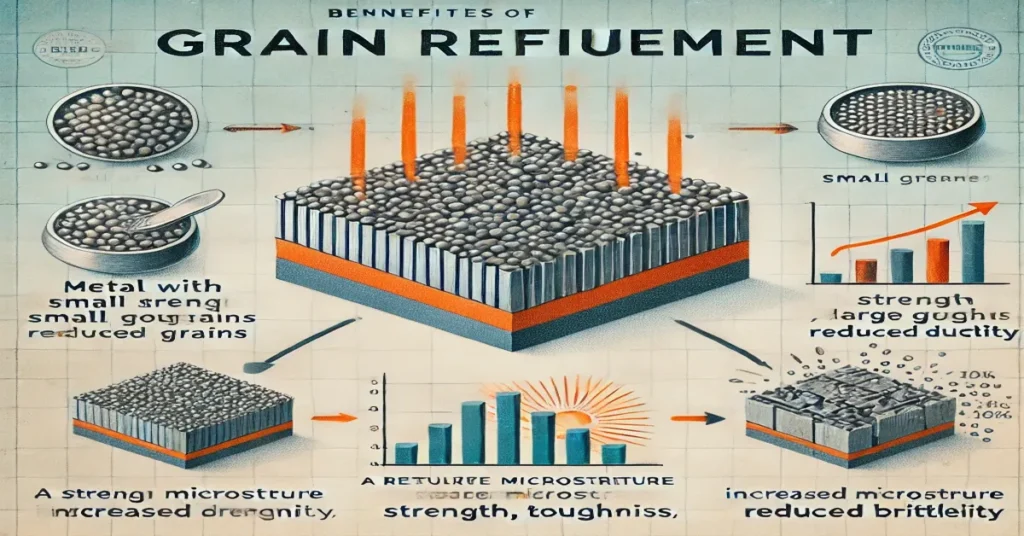

Grain refinement provides numerous benefits, especially in terms of enhancing the mechanical properties and performance of metals. Some of the key advantages include:

5.1 Increased Strength and Hardness

Due to the Hall-Petch effect, smaller grain sizes lead to increased metal strength and hardness. Fine-grained metals have more grain boundaries, which block dislocation movement and increase resistance to deformation. This enhancement is particularly valuable in metals used in structural applications, where strength is crucial.

5.2 Improved Ductility and Toughness

Grain refinement contributes to improved ductility, or the ability of the metal to deform without breaking. Smaller grains distribute stress more evenly, allowing the metal to absorb more energy before fracturing. This property is especially useful in applications that require metal components to withstand impact forces, such as in automotive and aerospace applications.

5.3 Enhanced Wear Resistance

Fine-grained metals are more resistant to wear because their hard surfaces better withstand friction and abrasion. This resistance is beneficial in tools, machinery, and structural components that experience constant mechanical stress.

5.4 Better Resistance to Cracking and Fatigue

In addition to strength, grain refinement improves a metal’s resistance to fatigue and cracking. Finer grains reduce the likelihood of crack initiation and slow down crack propagation, making the metal more durable under repeated or cyclic loading conditions.

5.5 Corrosion Resistance

For certain metals, grain refinement can improve corrosion resistance. For example, aluminum alloys refined with titanium-boron are more resistant to corrosion because fine-grained structures limit the formation of weak spots where corrosion can initiate.

6. Applications of Grain Refiners in Industry

Now that we know “what is a grain refiner” we move on to their applications. Grain refiners have applications across numerous industries due to their ability to enhance metal properties. Some of the primary applications include:

6.1 Aerospace Industry

In aerospace applications, where lightweight yet strong materials are required, grain-refined aluminum and titanium alloys are used to produce structural components. These metals provide high strength-to-weight ratios and improved fatigue resistance, making them ideal for aircraft frames and engine components.

6.2 “what is a grain refiner” In Automotive Industry

The automotive industry benefits from grain refinement in the production of strong, wear-resistant aluminum and steel components. Fine-grained metals are used in engine blocks, wheels, and transmission parts, where strength, toughness, and resistance to wear are essential for performance and safety.

6.3 Construction and Infrastructure

In construction, grain refinement is used to produce steel and aluminum materials with enhanced strength, wear resistance, and durability. Fine-grained steel is especially valuable in beams, bridges, and structural components, where resilience to stress and environmental factors is crucial.

6.4 Electronics and Electrical Applications

In the electronics industry, copper alloys with fine grains are commonly used in electrical wiring and components. Grain-refined copper has higher conductivity and greater resistance to cracking, which improves the reliability and efficiency of electrical systems.

6.5 Marine Applications

Grain refiners are used in alloys for marine applications where resistance to corrosion is essential. Refined aluminum and titanium alloys are used in shipbuilding and offshore structures, as these metals can withstand harsh saltwater environments.

7. Challenges and Considerations in Grain Refinement

While grain refiners offer numerous benefits, there are also challenges associated with their use:

7.1 Cost of Grain Refiners

Certain grain refiners, such as those containing rare metals like titanium or niobium, can be expensive. This cost may limit their use in industries where economic efficiency is critical, requiring manufacturers to balance cost with performance.

7.2 Compatibility with Metal Alloys

Not all grain refiners are compatible with every metal alloy. For example, certain grain refiners are only effective with aluminum alloys, while others work best with magnesium or titanium. Choosing the appropriate grain refiner for each application is crucial to achieving the desired metal properties.

7.3 Control of Grain Size

Over-refining can lead to excessively fine grains, which may adversely affect the metal’s properties, such as its machinability or brittleness. Proper control of the refining process is essential to achieving an optimal balance between strength and workability.

8. Future Directions and Innovations in Grain Refinement

Research and development continue to improve the efficiency of grain refiners, creating new methods to control grain size and distribution in metal alloys. Advanced techniques, such as using nanoparticles as nucleation sites, are being explored to enhance grain refinement further. These innovations may provide more cost-effective solutions, expand the applicability of grain refinement, and unlock new material properties.

Hope that you would have gotten your answer to the question of “what is a grain refiner” and how they are useful in the industries across many sectors.

Read More: Bio Enzymes: A Comprehensive Exploration of Their Ecological Niche